Information Page

With many Companies able to produce first class artwork on computers,

acid etching has become a very simple way of reproducing that artwork

on brass, stainless steel, bronze or aluminium. There are several

ways to go about acid etching and we talk to customers first to help

them decide on the best method for their production requirements. We

will also recommend the most suitable of our etching machines.

Press-n-Peel

This is primarily a PCB protyping system. It is a very fast and

convenient way of getting the resist onto the laminate. It can used

used with either a computer with laser printer or with a photocopier.

If you want to know more about this method then follow the link

below.

Screen Printing Method

If companies already have this "in house" then start up costs

for etching will only entail the purchase of an etching machine. This

is probably the most popular method for that reason. The plates are

screen printed with an acid resistant ink. A reverse image is printed

so that all the parts of the plate that are not to be etched are

protected. The plate is then etched ( See etching ).

After etching the resist is stripped off and the plate is ready to

infill.*

Note! It is possible to leave the ink on to act as a mask for

infilling but this requires both a particular type of ink and also a

particular type of infill paint.

*Stripping solution depends on type of ink used .

Acid resist screen inks are widely available around the world from

normal screen ink suppliers but we can also supply if required.

Computer Cut Vinyls

|

|

Companies with signmaking equipment can make a vinyl

mask, again to mask off the parts of the plate that are not

to be etched. Vinyl is a very good etch resist and allows

production of a wide variety of etched signs. This method is

limited to the capability of the system and is unable to

produce very fine line work or small letters. (See

etching). |

|

|

This method has the highest start up cost but is the

"state of the art" method. |

|

|

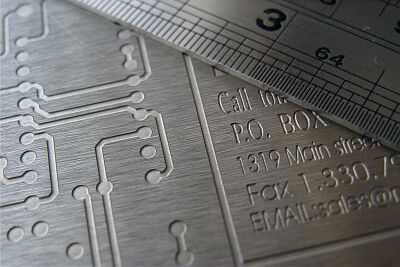

This picture shows the film and the finished product after etching and painting of the non-etched areas. The black areas on the film will be the etched areas of the plate. The clear areas will not be etched. |

|

|

The plate to be etched first has to be encapsulated in a special light sensitive film. Dry film photo-resist. The film is very light sensitive which is why the photo is yellow. It was taken in the darkroom under a yellow safe light. White light could render the whole roll of film useless. |

|

|

The next step is to imprint the image on the film by shining an ultra-violet light through the template film shown earlier. The film is placed on top of the plate and film, the unit is closed and switched on for a pre-determined amount of time. This exposes the areas not covered by the black areas of the template film. This is again carried out in a darkroom because of the light sensitivity of the film. The picture here is for display purposes only. |

|

|

Once the plate and dry film has been exposed the outer layers of the film are pulled off and the plates put through a developing process. The film will leave an etch resistant coating on the plate. The developing process will wash away the area that were not exposed to the uv light leaving the etch resistant coating on the rest. The uv light hardens the coating. |

|

|

The mechanics of the developer is exactly the same as the etcher. In this case it sprays developing fluid which strips away the unhardened (non-uv exposed) areas so that they can be etched. |

|

Note! |

It is important to inspect the plates prior to etching regardless of the method used to put a resist onto the plates. Once the plate is in the etcher then any exposed area will be etched so check for pinholes etc. in screen printed plates and dry film plates and for vinyl covered plates ensure that the film is well stuck down. Dry film photoresist is widely available around the world but we can supply if required. |

Etching

We manufacture a wide range of standard

etching machines from benchtop units to free

standing units up to machines for etching whole sheets of brass and

stainless steel.

|

|

The etching machines are conveyorised and the plates are fed into the machine where in the first chamber they are sprayed with Ferric Chloride at 45oC. A carryover gap is fitted between the etch chamber and the rinse chamber with pinch rollers to prevent carryover of solution from one chamber to another. The second chamber is a water rinse so that the plates go in and come out of the machine clean. This avoids the operator having to come into contact with the chemicals. The conveyor speeds are variable and the speed of throughput will determine the depth of etch. (See also Chemical Engraving). |